높은 내식성

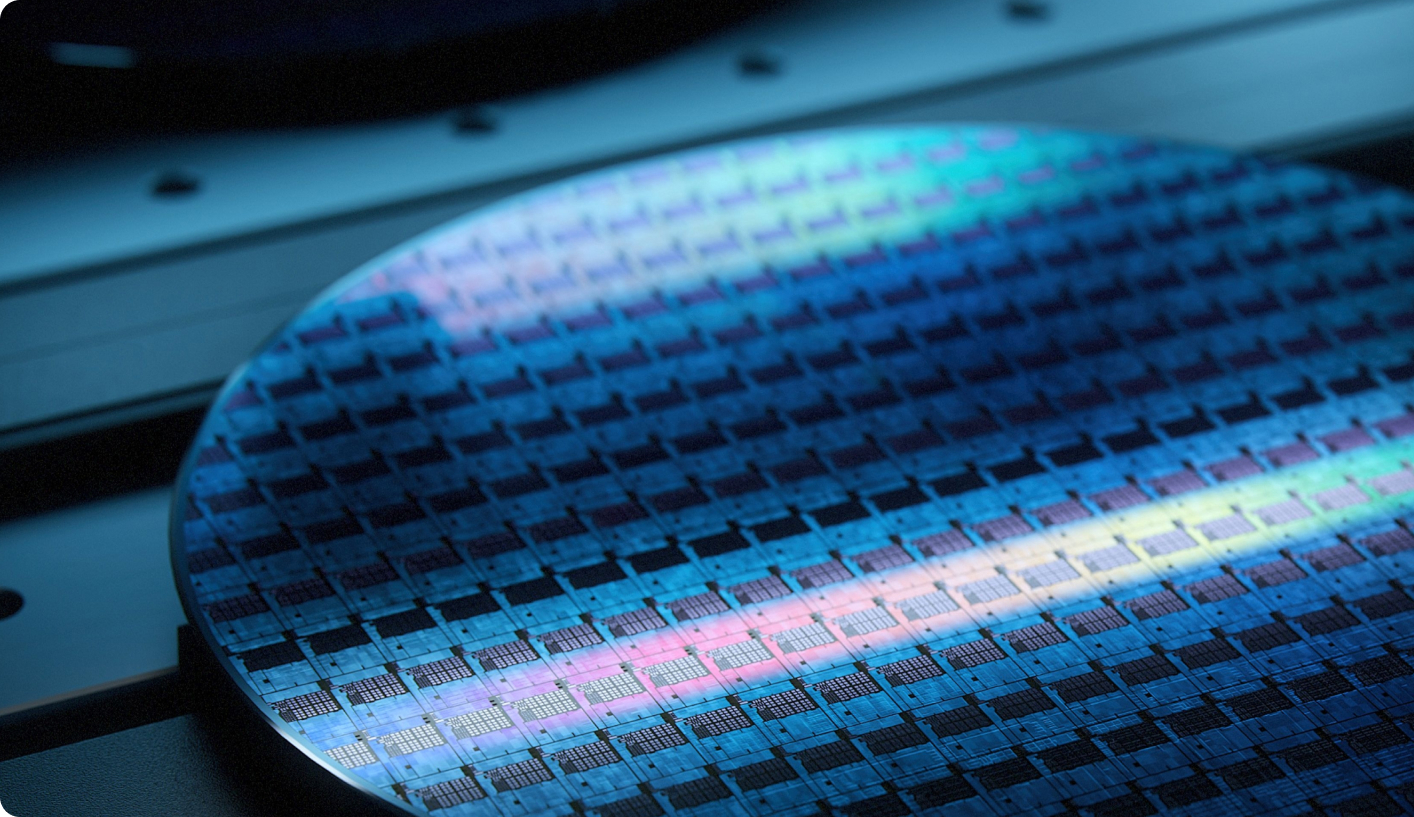

Bulk CVD SiC Components

CVD 공법으로 생산되는 제품으로 고온, 고압, 그리고 화학적 부식 환경에서도 뛰어난 내구성을 제공하는 고성능 소재로 반도체, 항공우주 및 에너지 산업에서 널리 사용되고 있습니다. 특히, 반도체 공정에서 사용되는 CVD SiC 부품은 높은 내구성과 안정성을 제공하여, 공정 수율을 개선하는 데 기여하고 있습니다.

제품 특성

높은 내화학성

Si 대비 긴 수명

열 변형 없음

반도체 공정에 적합한

고순도 입자

뛰어난 경도와 강도